Freakazoid: Competitive Battle Bot

Anteater Combat Engineering (ACE)

2025

1/Summary

Designed and manufactured a 1-lb BattleBot featuring a modular 3D-printed chassis optimized for lightweight durability and rapid part replacement.

Integrated a belt-driven spinning weapon system with custom tolerances for reliable engagement and minimized frictional losses during combat.

Validated structural performance through finite element analysis (FEA) and iterative prototyping, ensuring strength, maneuverability, and resilience under impact conditions.

2/Design Breakdown

Weapon + Weapon Hub

Weapon Design - Exploded ViewButton Head Torx Screw

Needle Thrust Bearing

Washer

Washer

Weapon Hub Bearing

Scalar Weapon Shaft

Weapon Belt

Weapon Hub

Weapon Hub Bearing

Horizontal Spinning Weapon

Washer

Washer

Needle Thrust Bearing

Button Head Torx Screw

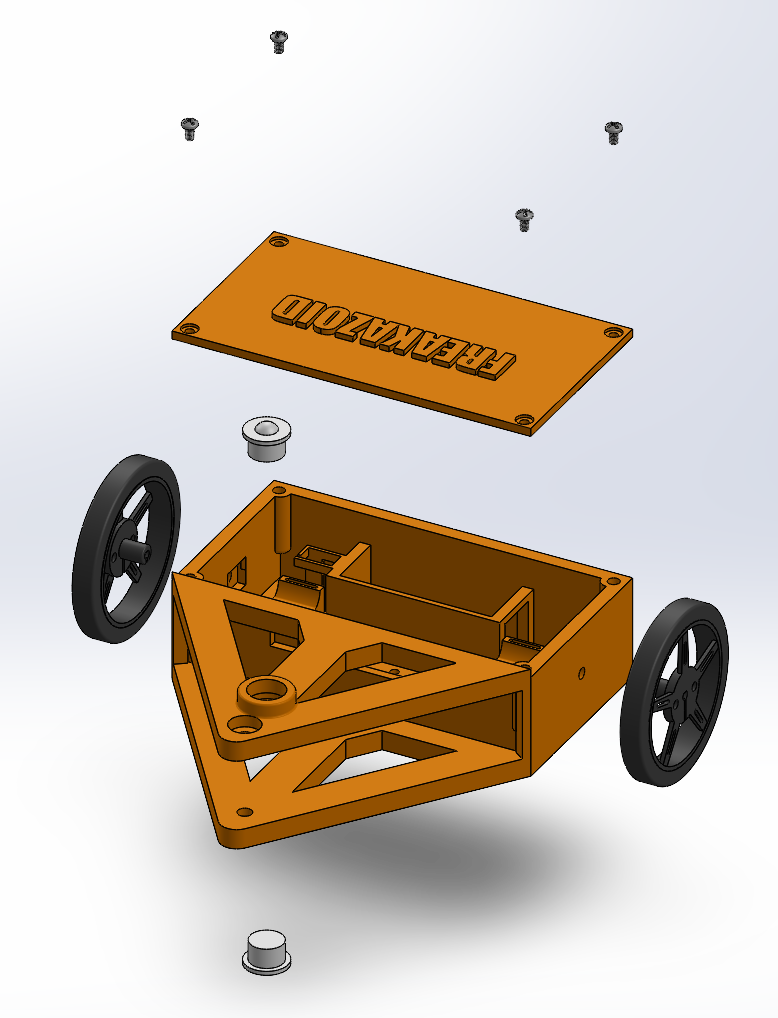

Chassis

Chassis - Exploded ViewM3 Pan Head Screw

M3 Pan Head Screw

M3 Pan Head Screw

Chassis Top Plate

Roller Bearing

Chassis Main Body

5 Spoke D-Shaft Wheels

Roller Bearing

Weapon Design

We transitioned from a blade-style weapon to a hammer design to increase striking reliability and energy transfer. The increased contact area reduces the risk of snagging on opposing bots while improving the bite and distributing impact forces more effectively. The hammer profile concentrates mass behind the strike face for higher impulse, while integrated cutouts reduce weight, refine moment of inertia for faster spin-up, and assist with balancing and manufacturability.

Motor Mounting Design

The chassis features a snap-fit system to secure the brushed motors without any external hardware. I designed complementary semi-cylindrical cutouts in the base and top plate, each conforming to half the motor profile. The interlocking geometry provides a precise press-fit, reducing part count, easing assembly, and maintaining stability under dynamic loads.